Ventilation System for an Underground Car Park

Ventilation System for an Underground Car Park

1. Objective

The system aims to:

Remove exhaust gases and carbon monoxide (CO).

Provide a healthy and safe environment during normal operation.

Ensure efficient smoke extraction in case of fire or emergency.

2. Basic Data

Car park area: 1,200 m²

Clear ceiling height: 3.0 m

Capacity: Approximately 40 cars

Total volume = 1,200 × 3 = 3,600 m³

3. Types of Ventilation

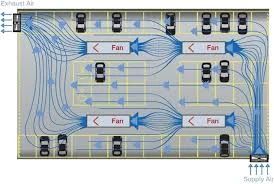

Normal (Operational) Ventilation: Automatically controlled based on CO concentration sensors.

Emergency (Fire) Ventilation: Activated by the fire alarm system to extract smoke and maintain safe escape routes.

Fresh Air Inlets: Distributed around the car park to ensure proper air replacement and balanced pressure.

4. Basic Ventilation Calculations

A. By Air Changes per Hour (ACH)

Recommended air change rate: 6 times/hour

Required airflow = 6 × 3,600 = 21,600 m³/h

Equivalent flow = 6.0 m³/s

B. By Flow Rate per Vehicle

Rate per car: 30 L/s

Total = 40 × 30 = 1,200 L/s = 1.2 m³/s = 4,320 m³/h

Comparison and Recommendation

The higher rate (6 ACH = 21,600 m³/h) should be adopted to ensure sufficient ventilation and safety margins against gas buildup.

5. Emergency (Smoke Extraction) Mode

Recommended air change rate during fire: 10 ACH

Required airflow = 10 × 3,600 = 36,000 m³/h ≈ 10 m³/s

Fans should be heat-resistant and interlocked with the fire alarm system for automatic operation during emergencies.

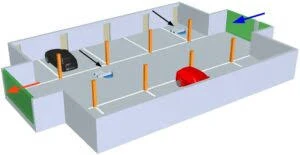

6. Fans Distribution and Mechanical Design

Number of fans: 2 operating + 1 standby (redundancy system 2+1).

Capacity per fan: ≈10,800 m³/h.

Estimated total static pressure: 500 Pa.

Power per fan: ≈3 kW.

Ductwork made of galvanized steel, maintaining internal air velocity between 6–8 m/s for efficiency and noise control.

7. Main System Components

Axial or centrifugal fans: Industrial-grade, fire-resistant, suitable for smoke extraction.

Duct network: Galvanized sheet metal ducts, optionally acoustically insulated.

Air inlets/outlets (Louvers): With motorized dampers for air direction control.

CO Sensors: Strategically located at 1.5–2.0 m height to monitor gas concentration and control fan operation.

Central control panel (PLC/VFD):

Variable speed fan control.

Integration with fire alarm system.

Manual and emergency override options.

Dedicated smoke exhaust shafts: Designed to discharge smoke away from escape routes and building entrances.

8. Safety Requirements

Integration with fire alarm system: Automatic switch to smoke extraction mode when fire is detected.

Manual emergency switches: Installed at exits and near control panels.

Heat-resistant fans: Rated for up to 300°C for 1–2 hours per code requirements.

Smoke containment: Air ducts designed to prevent smoke migration to residential or lift areas.

Regular maintenance: Ensures system readiness and compliance with safety standards.

9. Noise and Vibration Control

Sound attenuators (Silencers): Installed at fan inlets/outlets to minimize noise.

Anti-vibration mounts: Rubber isolators under fans and equipment.

Equipment placement: Away from occupied areas to reduce transmitted sound.

10. Operation and Maintenance

Quarterly inspection: Fans, filters, and CO sensors.

Annual calibration: Of CO detection system.

Routine cleaning: Of ducts, grilles, and louvers.

Emergency simulation: Twice per year to verify system response.

Maintain detailed logbooks for operation and maintenance activities.

11. Energy Efficiency

Use high-efficiency motors with Variable Frequency Drives (VFDs) to reduce energy consumption.

Smart control based on CO levels to operate only when necessary.

Incorporate natural ventilation openings where possible to reduce mechanical load.

12. Preliminary Cost Estimate

(Indicative and dependent on market prices)

3 fans (3 kW each) + control panel + CO sensors + duct system + installation

→ Estimated total cost: USD 15,000 – 25,000 (or local equivalent).

Actual cost depends on car park layout, equipment brands, and local code requirements.

13. Next Steps

Conduct site measurements to confirm dimensions and duct routes.

Review local building/fire codes (e.g., Egyptian Civil Defense or NFPA).

Perform CFD simulation to optimize air and smoke flow.

Prepare detailed drawings and Bill of Quantities (BOQ) for tendering.

Commissioning and performance testing prior to handover.

14. General Recommendations

Implement an intelligent control system integrated with fire and CO detection.

Equip all openings and fans with protective grilles and dampers.

Maintain CO levels below 50 ppm during operation (as per safety standards).

Use natural ventilation wherever feasible to improve efficiency.

Provide training for building staff on emergency operation and evacuation.

15. Conclusion

The proposed ventilation design for an underground car park ensures:

User safety from toxic gases and smoke.

Operational efficiency through CO-based automatic control.

Emergency reliability using fire-rated fans and integrated alarm systems.

Ease of maintenance and sustainability for long-term operation.

The recommended design rate (6 ACH for normal mode, 10 ACH for fire mode) offers a balanced, practical, and code-compliant solution adaptable to actual site conditions.