Engineering Report on the Sewage Pipe Network for a Residential City

An Engineering Report on Sewage Pipe Networks for Residential Cities

1. The Hidden Lifeline: Critical Role of Urban Sewage Networks

A sewage pipe network is a fundamental and critical component of urban infrastructure, efficiently collecting and transporting wastewater away from residential and commercial areas to treatment facilities. Its effective operation is essential for:

1.1 Public Health and Environmental Protection

Preventing the spread of waterborne diseases and ensuring contaminants do not pollute soil, groundwater, or surface water. This is vital for maintaining a clean and healthy urban environment.

1.2 Enhancing Urban Safety and Sustainable Growth

Mitigating risks like ground instability and unpleasant odors, and enabling population growth and urban expansion in a sustainable, clean manner.

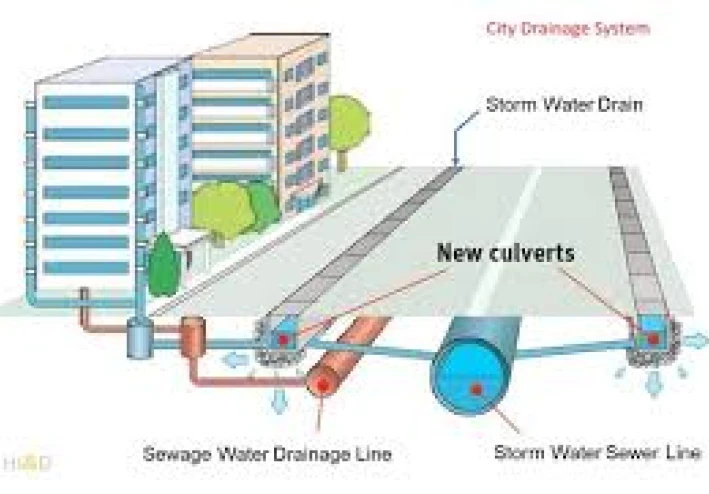

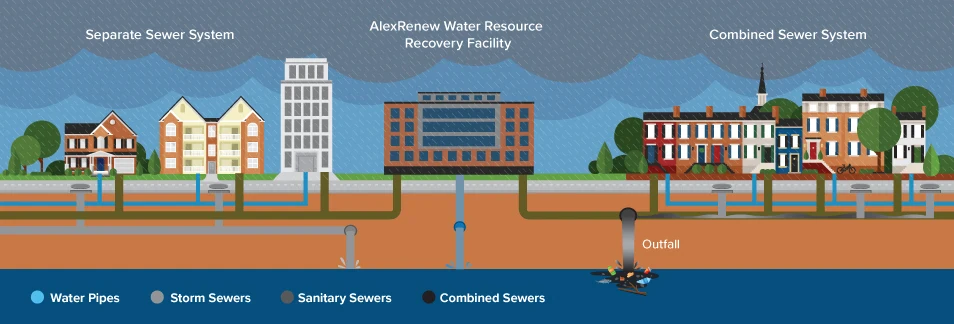

2. Network Anatomy: From Pipe to Pumping Station

The network is an integrated system of several vital components:

2.1 The Backbone: Materials and Sizing of Conduits

Pipes form the backbone, chosen based on cost, durability, and application.

Common Materials:

PVC: Used for internal connections and secondary lines (lightweight, corrosion resistance).

Reinforced Concrete: Preferred for large-diameter main pipes (withstands heavy loads).

HDPE: Used for pressure lines and unstable soil (flexibility, leak-free joints).

Standard Diameters: Ranging from small house connections ($100-200\ mm$) to large Main/Trunk Pipes (400-1200\ mm), depending on served population and projected flow.

2.2 Essential Accessories for Access and Functionality

These components ensure network functionality and accessibility.

Manholes: Access points installed at regular intervals (typically 50-100\ m), junctions, or changes in direction for inspection, cleaning, and maintenance.

Pumping Stations: Used when gravity flow is impossible due to topography, lifting wastewater to a higher elevation to resume gravity flow.

Screens and Valves: Screens block large debris from damaging pumps; Air Release Valves prevent airlocks in pressure lines.

3. Engineering Design: Achieving Optimal Gravity Flow

A well-designed network is efficient, cost-effective, and sustainable:

3.1 Hydraulic Calculations: Ensuring Self-Cleansing Velocity

This is the core engineering phase to ensure "self-cleansing" flow.

Flow Estimation: Calculated based on population density, average water consumption, and a "peak factor" (usually $1.5$ to $3$) to account for maximum flow times.

Optimal Flow Velocity: Flow speed must be maintained between 0.6\ m/s (to prevent solids settling) and 3.0\ m/s to prevent pipe erosion).

Sizing the Pipes: Using hydraulic formulas (like Manning's equation) to determine the pipe diameter and slope to achieve the required velocity and capacity.

3.2 Strategic Routing and Layout Planning

The network's physical path must be strategically planned.

Gravity Priority: The system relies on gravity as much as possible to minimize operational energy costs.

Adequate Slope (Gradient): A minimum slope is typically maintained to ensure self-cleansing velocity.

Topography: Main pipes are generally laid in the lowest parts of the area to naturally collect flows.

4. Quality, Safety, and Compliance Standards

Adherence to strict standards is non-negotiable for long-term performance:

4.1 Material Durability and Leak Prevention

Pipes must be resistant to chemical corrosion, abrasion, and structural loads. Leak-proof installation using proper jointing techniques is crucial to prevent both exfiltration (sewage leaking out) and infiltration (groundwater leaking in), which can overload the system.

4.2 Monitoring and Regulatory Compliance

Installing flow meters and pressure sensors helps in proactively identifying issues. All materials and construction practices must conform to local codes and international standards (such as ASTM, EN, or ISO).

5. Operations and Maintenance: The Key to System Longevity

Proactive maintenance is essential to prevent system failures and expensive emergencies:

5.1 Digital Inspection and Preventive Cleaning

Regular Inspection (CCTV): Using specialized cameras to inspect the internal condition of pipes and identify cracks, root intrusion, or sediment buildup.

Preventive Cleaning: Employing high-pressure water jetting to remove grease, sand, and other deposits before they cause complete blockages.

5.2 Data Management and Emergency Preparedness

Keeping detailed records of all inspections and maintenance is invaluable for predictive maintenance and future planning. A clear action plan and dedicated team must be ready to respond quickly to emergencies.

6. Conclusion: An Investment in Urban Quality of Life

The sewage pipe network is an indispensable, though often unseen, lifeline of a modern residential city. Its continuous and efficient operation is the result of meticulous engineering design, the selection of high-quality materials, and a rigorous, proactive maintenance regime. Investing in a robust sewage infrastructure is a direct investment in public health, environmental protection, and the overall quality of life for all residents.