Design of a Fire Pump and Sprinkler Network for a 2000 m2 Plastics Storage Warehouse.

Firefighting System Design Report

Project: Design of a Fire Pump and Sprinkler Network for a 2000m2 Plastics Storage Warehouse.

Date: [Date of Preparation]

1. Requirements Analysis and Initial Classification

1.1 Inventory Classification and Hazard Type

The inventory was practically classified as exposed Group A plastics stored up to 5meters. This scenario is typically treated as a High Storage Hazard (approaching Extra Hazard), or requires ESFR/in-rack solutions depending on the storage method. A Conservative High Storage Design criterion was selected due to the high heat release rate and flammability of plastics.

2. Design Density and Flow Rate Determination

The hydraulic requirements were established based on the high hazard classification.

2.1 Design Density Selection

A conservative design density of 0.30gpm/ft2 was selected, which is equivalent to approximately 12.224L/min⋅m2. This is a common value for protecting plastic commodities and high-bay storage using ceiling-only or in-rack designs, as applicable.

2.2 Calculation of Total Design Flow Rate

Based on the warehouse area of 2000m2 and the chosen density, the total design flow rate (Q) required is:

Q=12.224min⋅m2L×2000m2=24,447.5L/min

Converting the flow rate to larger, more practical units:

Q≈407.46L/sor24.45m3/minute

3. Preliminary Pump and Reservoir Specifications

3.1 Initial Pump Pressure Estimate

The pump pressure depends on the total friction loss, elevation difference, and the minimum pressure required at the sprinklers. For high-rack storage and plastic inventory, an initial operating pressure ranging between 6.0 and 7.5bar at the pump discharge is recommended. Detailed hydraulic calculations must be performed subsequently to determine the final value.

3.2 Water Reservoir Size Determination

If the municipal water supply cannot provide the flow continuously, a reserve tank is required for a standard duration (30 or 60 minutes).

For a 30-minute duration: The required tank volume is ≈733.4m3.

For a 60-minute duration (Conservative Option): The required tank volume is ≈1,466.9m3.

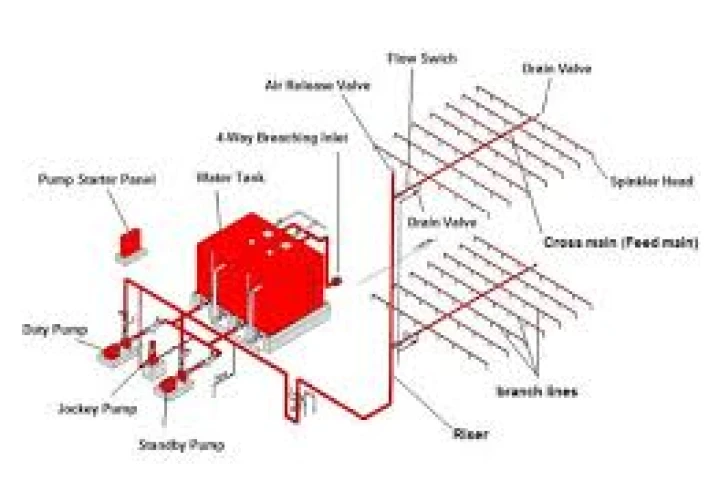

3.3 Pump Specifications and Accessories

A Centrifugal Fire Pump is recommended, with a nominal capacity near 410L/s at 6.0 to 7.5bar pressure. The system must include: a Jockey Pump (for pressure maintenance), an NFPA-compliant fire pump controller, check valves, and a test header.

4. Preliminary Piping Network and Sprinklers Description

4.1 Sprinkler Type Selection

Due to the nature of plastic goods, two practical options must be evaluated:

ESFR (Early Suppression Fast Response) Sprinklers: The preferred option for high-rack storage warehouses.

Traditional High-Density Design with In-rack Sprinklers if the ESFR option is not feasible or appropriate.

4.2 Main Pipe Diameter Estimation

To achieve a flow of 0.407m3/s at an acceptable velocity (2 to 3m/s), the preliminary diameter for the main pipes is estimated to be between Ø400 mm and Ø500mm. A looped mains network design is preferred to ensure bi-directional flow.

4.3 Identification of the Most Remote Area (MRA)

The MRA is defined as the hydraulically most demanding area or group of heads, requiring the maximum flow and pressure from the pump. This is the point where the highest pressure loss occurs (due to pipe length), in addition to elevation difference. Practically, this is often the corner furthest from the pump or the end of deep rack aisles inside the warehouse. The detailed hydraulic calculation must be centered on ensuring optimal performance at this location.

5. Summary and Necessary Recommendations

Key Recommendations:

Detailed Hydraulic Calculations must be performed using modeling software (NFPA/FM) to accurately determine final pipe diameters and residual pressures.

Storage Arrangement Confirmation: Verify the type of racks and packaging to determine the actual need for ESFR or In-rack sprinklers.

Operational and Maintenance Procedures: Conduct acceptance testing on-site after installation and implement a periodic maintenance protocol.