Overhead (( Elevated )) Water Tank Design Report

Engineering Report on Overhead Water Tank for Urban Water Supply

1. Introduction

The overhead water tank is one of the most essential components of the urban water distribution system. It is used for storing water and ensuring a continuous and stable supply, especially during peak demand periods, power outages, or temporary shutdowns of pumping stations.

The tank is typically constructed at a specific elevation above ground level to provide sufficient hydraulic head for water distribution throughout the network without continuous reliance on pumps.

2. Purpose of Constructing the Overhead Water Tank

To provide a reserve water storage for use during emergencies or interruptions in pumping.

To regulate pressure within the distribution network and balance between pumping and consumption periods.

To meet peak demand requirements when water consumption increases at specific times of the day.

To ensure uninterrupted water supply to residents and maintain service continuity.

3. Components of the Overhead Water Tank

The overhead tank typically consists of the following parts:

Main Tank:

The primary storage body, constructed of reinforced concrete, galvanized steel, or fiberglass, designed according to the required capacity.

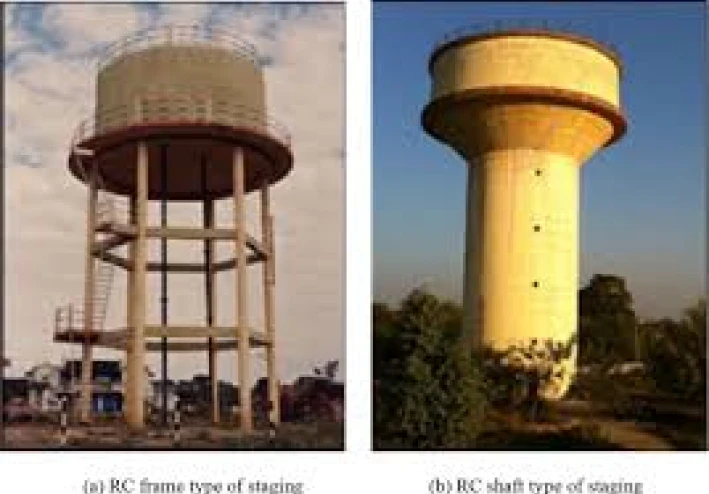

Supporting Tower or Columns:

Structural elements that elevate the tank to the required height, ensuring adequate pressure in the distribution network.

Piping System:

Inlet Pipe: Supplies water from the pumping station or ground reservoir.

Outlet Pipe: Distributes water to the main supply network.

Overflow Pipe: Discharges excess water when the tank is full.

Drain Pipe: Used to empty the tank during cleaning or maintenance.

Access Openings and Ventilation Covers:

Fitted with airtight lids for inspection, maintenance, and ventilation.

Metal Ladder and Safety Railings:

Provide safe access for inspection and maintenance work.

4. Engineering Design of the Overhead Tank

a. Determining Required Capacity

The required capacity depends on the number of inhabitants, average daily consumption per person, and desired storage duration.

Required Capacity (m³)=Population×Daily Consumption per Capita (L)1000\text{Required Capacity (m³)} = \frac{\text{Population} \times \text{Daily Consumption per Capita (L)}}{1000}Required Capacity (m³)=1000Population×Daily Consumption per Capita (L)

b. Determining the Height

The height is calculated to provide sufficient pressure within the network:

Pressure (bar)=Height (m)×0.1\text{Pressure (bar)} = \text{Height (m)} \times 0.1Pressure (bar)=Height (m)×0.1

Typically, tower heights range from 20 to 40 meters, depending on the topography and network layout.

c. Selection of Materials

Reinforced Concrete: for large-capacity tanks.

Steel or Fiberglass: for medium and small capacities.

d. Load Calculations

Design loads include:

Self-weight of the tank structure

Weight of stored water

Wind loads

Seismic forces (in earthquake-prone regions)

5. Operational and Sanitary Considerations

Tanks must be cleaned periodically to prevent the buildup of algae and bacteria.

Internal surfaces should be coated with non-toxic, corrosion-resistant paint.

Install control valves and safety relief valves to ensure safe operation.

Use electronic water level sensors for real-time monitoring and automation.

6. Importance of Overhead Tanks in Urban Networks

Ensure balanced water distribution to all neighborhoods, especially those distant from pumping stations.

Act as hydraulic balancers within the water distribution network.

Reduce energy consumption by minimizing the need for continuous pumping.

Provide strategic water reserves for emergencies such as fires or power failures.

7. Conclusion

The overhead water tank is a vital infrastructure element in modern cities, ensuring efficient and reliable water supply to residents.

Its design is based on precise engineering principles that consider pressure requirements, capacity, material selection, and safety and maintenance aspects.

Investing in overhead water tanks represents an investment in the sustainability of water resources and the well-being of citizens.